Resembling a futuristic version of a holiday workshop, Amazon’s Bolton fulfillment center has become a hive of automated activity. Behind the scenes, a fleet of approximately 2,000 robots is redefining the logistics of online shopping, working silently to ensure packages reach doorsteps with unprecedented speed.

The Robotic Workforce

The facility operates on a model of seamless collaboration between humans and machines. Instead of employees walking miles through warehouse aisles to retrieve items, the robots do the heavy lifting.

These autonomous units are programmed to transport storage pods directly to workstations, significantly reducing physical strain on staff and increasing efficiency.

Smart Sorting and Speed

The technology goes beyond simple transport. The system utilizes advanced automation to streamline the entire process:

- Automatic Scanning: Barcodes are read instantly to track inventory.

- Intelligent Layouts: Algorithms analyze the contents of each pod to determine the optimal placement for goods.

- Conveyor Efficiency: Once items are picked, conveyors whisk them away to packing stations for final dispatch.

According to Amazon, this heavy reliance on automation is the key to managing the surge in volume, particularly during the peak holiday season.

By letting robots handle the logistics, the facility can process rising orders and ship parcels within hours of a purchase.

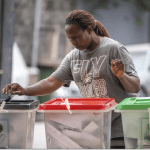

Confusion Mounts in Guinea-Bissau as Both Candidates Declare Victory